Technological Competitiveness

What’s better than existing technology

-

01

Foaming technology

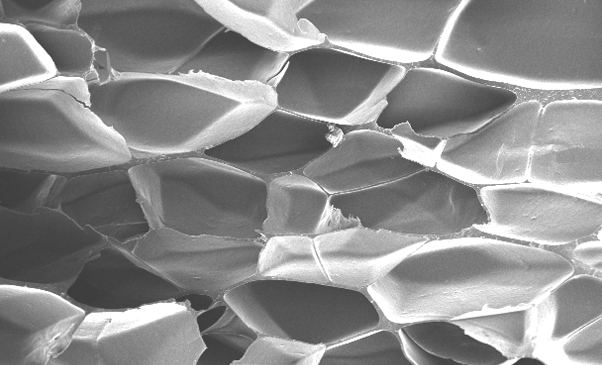

Proprietary BGFecosolution technology applied to give PLA foaming properties

-

02

Foam extrusion technology

Propriety foaming process

for PLA foam -

03

Thermoforming technology

Product design and thermoforming

technology appropriate

for PLA foam

BGFecosolution has developed

a range of technology

- BGFecosolution owns patents including PLA foam-optimized process technology.

- BGFecosolution’s proprietary foaming technologies produce foam sheets and thermoformed products.

- By overcoming difficulties of foaming PLA and giving PLA foamability, BGFecosolution can improve PLA functionality and reduce production costs.

- BGFecosolution owns patents including PLA foam-optimized process technology.

- Production of homogeneous PLA foam, which is impossible to achieve using conventional plastic foaming processes.

- Superior mechanical properties - thermal resistance, durability, insulation and cushioning - for substitution of conventional single-serve products made with PS, PP or pulp, etc.

Core Technology Development Milestones

Jul. 2003~

- PLA foam sheet developed

- PLA non-foam sheet and coating/laminating technology developed

- Environmentally friendly biodegradable resin compounding technology developed

- Dedicated PLA foam extrusion mechanical device developed

- PLA foam sheet pressure and vacuum molding developed

- PLA thermal resistant foam sheet developed

- PLA antibacterial sheet and molded products developed, PBAST raw material and foam sheet developed

to present

Competitive Advantage

| Item | Petroleum-based plasticfoam (Styrofoam) |

BGFecosolution core technology (PLAfoam) |

Remarks |

|---|---|---|---|

| Strength of foam product | △ ~ ○ | ◎ | - |

| Food contact safety | Harmful substances (endocrine disruptors) |

No harmful substances (endocrine disruptors) |

Fully FDA compliant |

| Biodegradability | X | O | 90% or greater biodegradation |

| Compostability | X | O | Compostability for industrial applications |

| Soil toxicity | Microplastics, endocrine disruptors | No Soil toxicity | Soil toxicity testing |

| Recyclability | △ | ◎ | Cross-linked PS unrecyclable; Recovered PLA is recyclable |

| Incineration characteristics | Quick combustion, dark exhaust fume, harmful gases | No dark exhaust fume and no harmful gases | With increased PLA use, incineration has potential as an environmentally friendly electric power generation option |

| CO2 reductions | X | ◎ (CO2 neutral) |

PLA is plant-derived, with less CO2 generated compared to conventional products from raw materials preparation to final production |

| Antibacterial properties | X | ◎ | BGFecosolution produces PLA foam products with antibacterial properties |

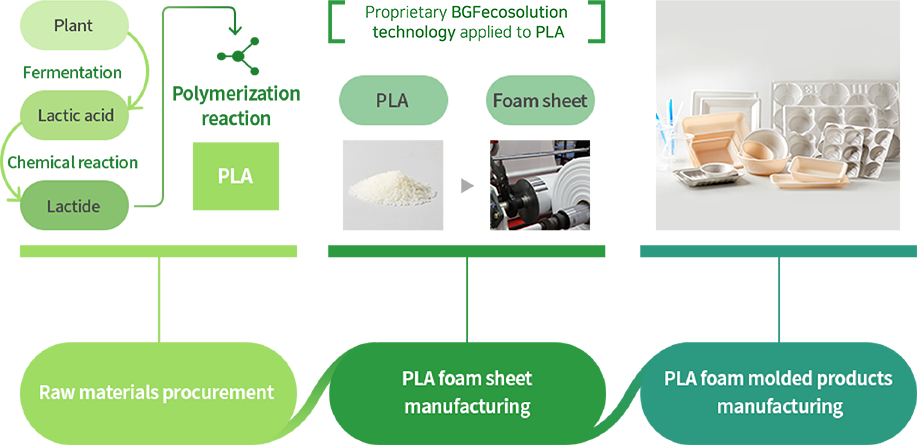

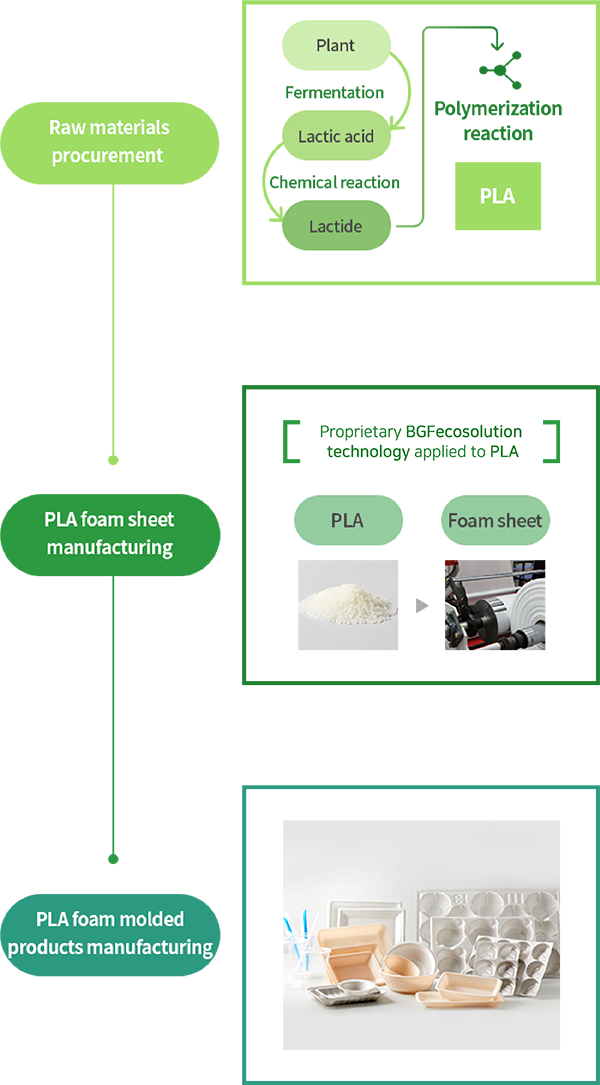

Production Process

Production process